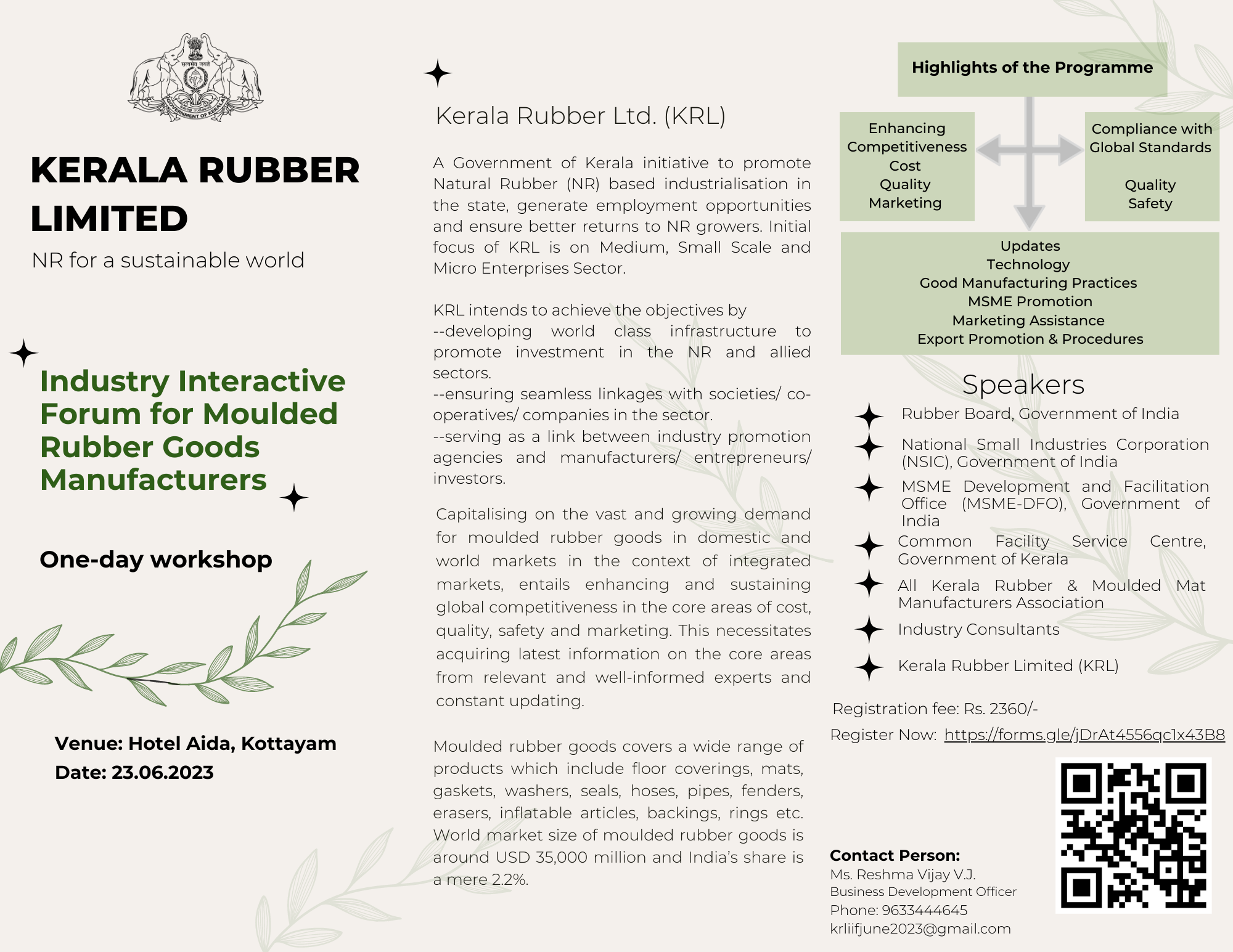

Kerala Rubber Limited (KRL) is a pioneering initiative by the Government of Kerala, aimed at transforming the state’s natural rubber industry through technology, innovation, and a focus on sustainable development to bolster international competitiveness. With a mission to harness the advantages of Kerala’s robust natural rubber production, KRL seeks to establish integrated facilities that will position the state as a major manufacturing hub for natural rubber-based and ancillary industries. This effort particularly emphasizes the growth of the MSME sector, creating a platform for small and medium enterprises to flourish within a globally competitive framework. Through strategic investments, cutting-edge research, and environmentally conscious practices, KRL is set to drive forward the state’s vision for economic progress rooted in sustainable industry practices.

Rubber Industry’s Sustainability

About KRL

A Kerala government initiative, in transforming the natural rubber industry through technology and innovation for international competitiveness and sustainable development.

Research and Development Centre

Kerala's rubber industry seeks public sector R&D for affordable expansion and product diversification, ensuring quality.

Testing and Quality Control Centre

Establishing a central rubber park ensures rigorous testing and certification for rubber products, fostering development in the industry.

Business Incubation Centre

Supports rubber product trade by providing expert assistance and government services to ensure quality standards.

Rubber Products Sterilisation Centre

It aims to utilize cutting-edge technologies to sterilize latex products, facilitating their global marketing and ensuring compliance with safety and quality regulations.

Our relentless pursuit of perfection, upheld through rigorous quality control measures at every production stage, guarantees that each product exceeds expectations, offering unparalleled reliability and longevity.

100% Natural

Rubber sourced entirely from natural origins.

High Tech Processing

A comprehensive facility comprising a Tyre Powdering Unit, a Tyre Testing Centre, a Central Tool Room, Engineering workshop, Mixing Plant, Latex Compounding, Pre-vulcanization, and a modern Common Effluent Treatment Plant (CETP).

Best Quality Products

Guarantees premium latex products adhere to global standards with advanced sterilization methods.

Registration Process

Interested parties gather industry requirements, regulations, and necessary documentation, register, prepare a detailed business proposal, and submit it for review.

Space Allocation

The allocation process culminates in the official handover of the inspected and agreed-upon space, marking the beginning of industry operations.

Proposal Evaluation

After initial review, proposals undergo detailed evaluation, followed by presentation for feedback and potential revision.

Proposal Sanction

After meticulous review and adjustments, grants final approval and issues a sanction letter, delineating terms and confirming project progression.

Guaranteed Quality

testimonials

What Our Customer Says

Opinions

Evaluations

Critiques

Our Vision

Develop world-class infrastructure to promote value addition in natural rubber through public-private investment in the sector, thereby creating a stable market for natural rubber, ensuring consistent returns to natural rubber growers, and contributing to the state's economic development.

Questions and concerns about our services and various applications

What is the primary focus of the Business Incubation Centre in relation to rubber products?

The Business Incubation Centre focuses on facilitating imports and exports of rubber products.

How can the establishment of a central rubber park contribute to the improvement of testing and certification measures in the rubber-based industries?

By providing a centralized location for end-to-end testing of latex, a central rubber park can ensure that rubber products meet standard-level certification, addressing the current deficiency in attaining quality certificates and fostering development in rubber-related industries.

Why is it advisable for rubber manufacturing units in Kerala to acquire Research and Development (R&D) from the public sector instead of the private sector?

Acquiring R&D from the public sector is recommended for the rubber manufacturing units in Kerala to facilitate the steady expansion of the industry, enable diversification of existing rubber products, and ensure product quality, as private sector R&D is considered expensive.

How does the Business Incubation Centre address the knowledge gap in trading rubber products?

The Centre facilitates assistance from experts and provides support to access services from the Government and promotional institutions to ensure product quality standards are met.

Our Blogs

Latest news